LUMiCheck® Product information

LUMiCheck® - The first step in dispersion analysis

| Measure differences between up to 8 samples | Quickly rank samples |

| Measure up to 8 samples at the same time | Operate instrument via touch-screen |

| Analyze concentrated samples | Lightweight, sturdy, compact |

| Handle any dispersing media: water, oil, solvents | Use disposable cells |

The Demixing Tester LUMiCheck® is a measuring instrument for the use in research, development and quality control laboratories.

It is used for the fast stability analysis and particle characterization of dispersions, with respect to the comparison of samples of similar type. Up to 8 concentrated or diluted dispersions can, independent of each other, be measured in different sample cells. The instrument is operated using a touch screen.

The easy operation of the instrument using a touch screen, data storage on a SD memory card as well as the optional battery operation permit the use in many field applications and in all kinds of environments and temperatures.

Fast quantitative comparison between samples and qualitative characterization of demixing behaviour, flocculation, sediment formation and stability result in LUMiCheck® applications for beverages and food, construction material, lubricants, fuels as well as for further emulsions and suspensions.

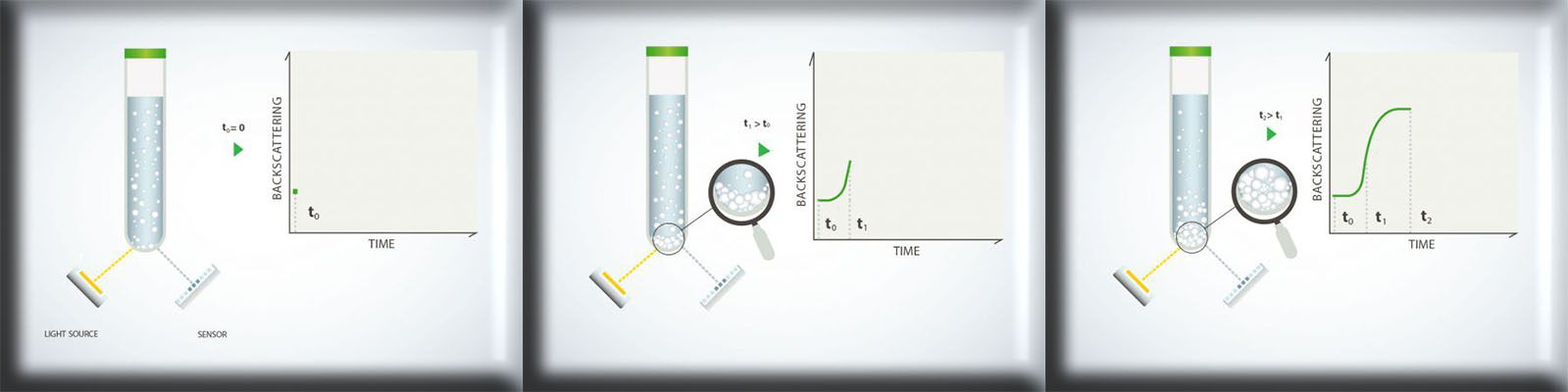

LUMiCheck® Technology

The LUMiCheck works on the back-scattering principle. Light scatters when a dispersed phase (consisting of particles and droplets) has a different index of refraction than the continuous media. The intensity of the scattering light depends mainly on the index of refraction, concentration, and particle size.

By following minute fluctuations and changes in the light scattering intensity, you can measure any changes in your sample. The LUMiCheck measures the light that is back-scattered at the bottom cross-section of specially designed cuvettes as a function of time. The use of special high-powered light-emitting diodes ensures that the scattering signal is of highest quality.

You can then measure the light-scattering signal over any time period you want, using optical sensors that can detect even the smallest changes occurring in your suspension or emulsion in real time.

LUMiCheck® Software

SEPView® - Your window to dispersion analysis

SEPView® - Your window to dispersion analysis

| Windows 7 and 8 based | plug and play, pack and go |

| Compare up to 8 different measurements | Complies with 21 CFR Part 11 |

SEPView® is a comprehensive database driven software solution.

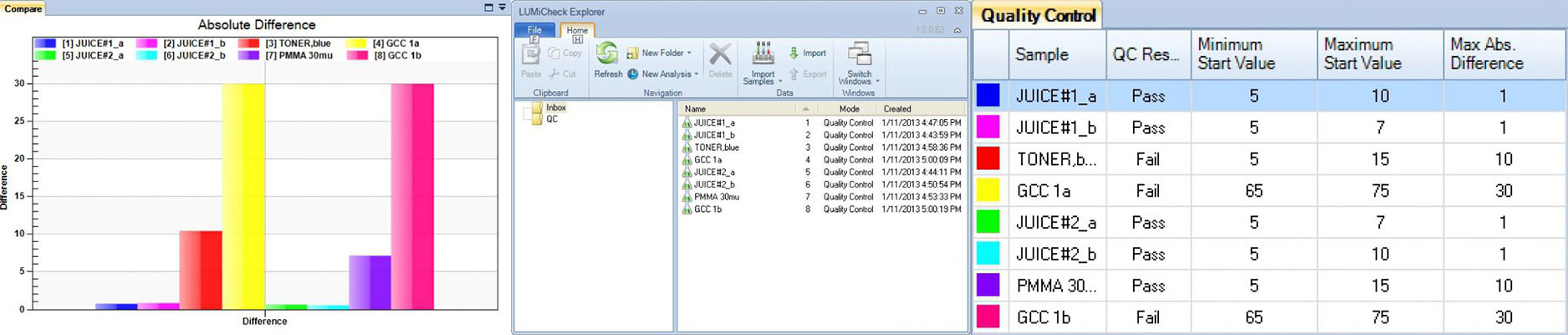

A special version of SEPView®-software comes with the LUMiCheck. It manages the data in Windows- Explorer style and uses a modern and intuitive ribbon user interface.

The software assists you in easy automatic data transfer from SD-Card for storage and further evaluation on your PC. You can effectively manage and analyze your data, compare different measurements e.g., by bar charts, create reports and share results with your colleagues via Excel, PDF or Word.

SEPView controls the instrument and provides functions for data management, visualisation, analysis and result documentation.

Fast access to validation and measurement results and sample information is guaranteed. Comparison of sample data from different measurements is easily achieved.

The program supports different languages and different systems of units. The modular and object oriented design of the software provides easy extension and customizing opportunities on customer's request, i.e. for special QC tasks. SEPView complies to CFR 21 Part 11.

LUMiCheck® Industrial Application

The modern measuring equipment made by LUM for comprehensive qualitative and quantitative characterization of dispersions is used in a large variety of different industrial and research facilities, dealing with innumerable materials.

To name few examples:

Bitumen

Petrol

Crude oil

Heavy fuel

Ceramic material

Cosmetics and Pharmaceutical products:

- Creams

- Hair care products

- Body care products

- Veterinary medicine

- Tooth paste

Food:

- Baby and infant food

- Dressings and sauces

- Functional food

- Beverages

- Ketchup

- Milk and milk products

Cosmetics and Pharmaceutical products:

- Creams

- Hair care products

- Body care products

- Veterinary medicine

- Tooth paste

Lubricants and coolants

Paints, Lacquers, Pigments and Inks:

- DIY- and industrial paints

- Automotive lacquers

- Printing inks

- Pigment dispersions

Polymers and Latices, Sludges, Slurries, Technical Dispersions

LUMiCheck® Specification

| sensitive test of phase separation | detection of the initial creaming / sedimentation |

| Simple and fast stability ranking | comparison of samples of same type |

| Hydrodynamic density determination | zero velocity approach, based on buoyancy |

| Observation time | 1 s to 23 h |

| Samples | 8 individually operated |

| Volume | 1 - 3 ml. |

| Light source | single wavelength for each sample |

| Temperature control | by ambient temperature 4 - 40 °C (can be operated in refridgerator or oven) |

| Cells | self-adjusting different materials |

| Disturbance free | no moving parts |

| Operation | LCD touchscreen |

| Data storage | SD memory card |

| Dimensions (WxHxD) | 23.6 x 11 x 26.5 cm |

| Weight | 2 kg |

| Power supply | Battery or AC voltage supply, 100 - 240 V, 50 - 60 Hz |