LUMiReader® Product information

LUMiReader® and LUMiReader® PSA - Going places the naked eye never could.

| Measure stability directly | Accelerate your dispersions up to 10x at 1g conditions |

| Immediately see and understand your complete dispersion behaviour from top to bottom | Differentiate between the various instability phenomena |

| Analyze concentrated samples | Investigate temperature effects up to 60° |

| Handle any dispersing media: water, oil, solvents | Use disposable cells |

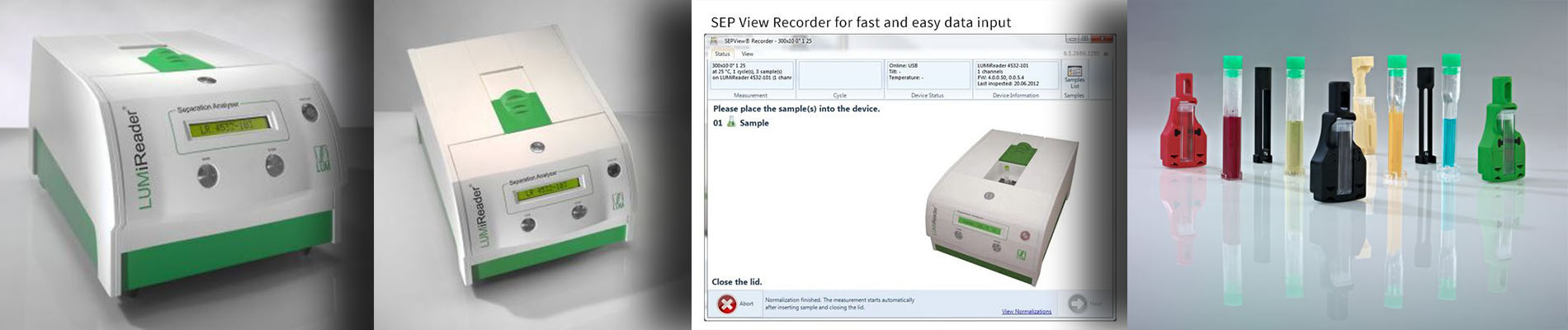

The LUMiReader® instantaneously measures the extinction profile of the transmitted light across the entire length of your sample. Each LUMiReader contains an optical block and temperature control element, each of which can be controlled individually. This ensures maximum flexibility and accuracy.

In addition, the specially designed PSA module also opens new horizons for high resolution particle sizing and allows you to measure the velocity distribution of separating particles. There is no need for you to know any material constants such as viscosity or density.

Our proprietary design ensures that the light strikes the sample across its entire height with minimal intensity variation or light bending, ensuring maximum sensitivity and reproducibility.

Each optical detector has more than 9,000 high-sensitivity micro-scale resolution sensors capable of accurately measuring even the smallest local changes instantaneously across the entire sample height.

This design eliminates the time-consuming and less accurate task of scanning your sample, allowing you to capture any micro-changes occuring in your dispersion.

The LUMiReader also uses a patented tilt technology based on the Boycott effect. The well-known principle allows an increase in the separation rate at 1 g without any additional external forces by tilting the sample from its normal upright position. The magnitude of acceleration (up to 10 times) depends on geometric factors, such as tilt angle, vial dimensions, and sample type.

Analyse under a wide range of viscosities, temperatures, and concentrations. With the advantage of looking at the entire sample from top to bottom instantaneously, you can observe and understand different stability/instability phenomena concurrently; for example, creaming, sedimentation coalescence, aggregation and flocculation at original product concentration.

The LUMiReader® comes certified, factory pre-calibrated and is ready-to-go.

LUMiReader® Technology

![]() STEP-Technology® – Allowing you to look at the whole sample.

STEP-Technology® – Allowing you to look at the whole sample.

Demixing phenomena, like sedimentation, flotation or consolidation are directly measured by the LUMiReader®, LUMiFuge® or LUMiSizer® due to the patented STEP-Technology.

This permits to obtain Space- and Time-resolved Extinction Profiles over the entire sample length of up to 12 different samples simultaneously. Parallel light (I0) illuminates the entire sample cell and the transmitted light I is detected by thousands of sensors arranged linearly across your whole sample from top to bottom with a microscale resolution. Transmission is converted into extinction by lg I/I0 and particle concentration may be calculated.

The unique STEP-Technology gives high flexibility to use different cells to match specific sample properties.

By means of the comprehensive database based PC-software SEPView the light intensity can be adjusted to the corresponding sample turbidity. Transmission profils are recorded as fast as each second or with time intervalls up to hours, displayed as a sequence on the screen.

Transmission date are automatically stored in a special designed database, together with all instrument settings and actual calibration data.

The speed of the centrifuge can be set at a constant value or programmed to change during the measurement in the range from 200 rpm to 4000 rpm. These rpm-values correspond to relative centrifugal forces (RCF) at the bottom of the cell of 5 to 2300 (RCF = centrifugal acceleration/earth gravity). Built-in temperature control covers all present and future applications.

Evaluation Features: The evolution of the transmission profiles contains the complete information on the kinetics of any concentration changes due to creaming, sedimentation, flocculation, coalescence or phase separation.

Based on these space- and time-resolved extinction profiles (STEP) demixing phenomena are quantified regarding clarification velocity, sedimentation and flotation velocity of particles, residual turbidity, separated phase volume (liquid or solid), sediment consolidation or dewaterability.

Furthermore, comprehensive infomation is obtained with respect to the multimodality or polydispersity of dispersed particles.

LUMiReader® Software

SEPView® - Your window to dispersion analysis

SEPView® - Your window to dispersion analysis

| Windows 7 and 8 based | plug and play, pack and go |

| Simultaneous instability index analysis at 3 wavelenghts in real-time | Individual user customization |

| Full SOP concept (Creation, capture, data analysis) | Windows Explorer based data management |

| PC- und serverbasierte Versionen verfügbar | Comprehensive database security and full audit log |

| Complies with 21 CFR Part 11 | 10 different tools to understand (quantify) even the most complicated dispersion: - Time lapse measurement replay - Dispersion fingerprint - Clarification - Instability index - Phase separation - Sedimentation and creaming velocities - Particle density and size distribution - First derivative of integral transmission - Multi-wavelength extinction ratio - Multi-wavelength particle size analysis |

SEPView® is a comprehensive database driven software solution. Whether you want to perform particle size measurements, stability analysis, determine creaming or sedimentation rates, predict shelf-life, examine flocculation and sedimentation consolidation, determine the degree of magnetization of your dispersed particles, or accurately calculate the particle density: with the help of SEPView you can do all this and more.

SEPView controls the instrument and provides functions for data management, visualisation, analysis and result documentation.

All information (calibration data, programmed measurement methods, comments, transmission profiles, settings etc) is stored in one database, no file management required.

Fast access to validation and measurement results and sample information is guaranteed. Comparison of sample data from different measurements is easily achieved.

Different program components are provided for the qualitative and quantitative analysis of the samples, e.g.

- for the clarification

- the Integral Transmission

- for settling, creaming & consolidation

- the Front Tracking

- the PSA-Module for the calculation of the particle size distribution.

The included animation tool displays the recorded measurement data with programmable playback parameters for easy recognition & identification of complex separation phenomena. Standard database functions like import & export of measurements and results, filtration of database content by various criteria, user and database administration are supported by SEPView.

The program supports different languages and different systems of units. The modular and object oriented design of the software provides easy extension and customizing opportunities on customer's request, i.e. for special R&D or QC tasks. SEPView complies to CFR 21 Part 11 for special R&D or QC tasks.

LUMiReader® Industrial Application

The modern measuring equipment made by LUM for comprehensive qualitative and quantitative characterization of dispersions is used in a large variety of different industrial and research facilities, dealing with innumerable materials.

To name few examples:

Bitumen

Petrol

Crude oil

Heavy fuel

Ceramic material

Cosmetics and Pharmaceutical products:

- Creams

- Hair care products

- Body care products

- Veterinary medicine

- Tooth paste

Food:

- Baby and infant food

- Dressings and sauces

- Functional food

- Beverages

- Ketchup

- Milk and milk products

Cosmetics and Pharmaceutical products:

- Creams

- Hair care products

- Body care products

- Veterinary medicine

- Tooth paste

Lubricants and coolants

Paints, Lacquers, Pigments and Inks:

- DIY- and industrial paints

- Automotive lacquers

- Printing inks

- Pigment dispersions

Polymers and Latices, Sludges, Slurries, Technical Dispersions

LUMiReader® Specification

| Accelerated phase separation | up to 10 times at gravity |

| Test time reduction through sensitivity | up to 250 times |

| Particle size distribution | 500 nm to 300 µm |

| Observation time | 0.5 s to unlimited |

| Conformity | ISO/TR 13097; ISO 13317; ASTM D7827, CFR 21 Part 111 |

| Samples | 1 sample |

| Volume | 0.5 ml to 4.0 ml |

| Concentration | 0.00015 Vol% - 75 Vol% |

| Particle density | up to 22 g/cm³ |

| Particle size | 200 nm to 2000 µm |

| Light source | multi-wavelength |

| Temperature control | ambient +3 °c to 60 °C, +/- 1K |

| Cells | different material and optical path |

| Dimensions (WxHxD) | 29x24x44 cm |

| Weight | 11 kg |

| Power supply | 24 V, Adapter (100 V to 240 V) included |