LUMiFrac® Product information

LUMiFrac® - The New Standard in Adhesion & Cohesion Testing

LUMiFrac® - The New Standard in Adhesion & Cohesion Testing

| Easy preparation of your test specimen | Up to 8 samples are analysed under identical conditions and with high reproducibility |

| No sample clamping at all - simply plug-in | Variable testing speed and adjustable loading progression |

| Versatile testing frequencies | Cost-saving multi-use of test stamps |

| Safety: capsuled housing | In accordance with ISO 4624 and DIN EN 15870 |

The Adhesion Analyser LUMiFrac® is the new benchmark for determining adhesive and tensile strengths (winner of the Berlin-Brandenburg 2012 Innovation Award, watch video HERE). The LUMiFrac employs centrifugal forces to stress multiple samples at once. It provides adhesive and tensile strength as well as shear strength as an absolute physical quantity in N/mm2.

The analyser accomplishes this by directly applying an incrementally increasing radial centrifugal force to the specimen being tested. It determines with high resolution the RPM at the moment of fracturing. All data is transmitted to the well-known and popular operating software SEPView, which automatically calculates and displays the critical force/strength of failure in real time.

Furthermore, it allows to analyze, compare & calculate statistics and combine results for up to tens of samples. Related data, as figures of fracture pattern, may be taken into account as well. Test sample positioning is as simple as 1-2-3. No clamping or special precautions are needed. Just slide up to 8 samples into marked rotor locations and you are ready to go.

The unique multisample approach of testing 8 samples simultaneously results in an unparalleled accuracy and reduces measuring time by 85%.

Starting as an idea for an easier and time-saving determination of adhesive properties, the multipatented new adhesion testing technology now revolutionizes the analysis of your composite materials and bonded parts. You can even work with multi-layered films; having an immense variety of applications.

The LUMiFrac is a research and QC tool for the adhesive formulation and surface treatment industry; lacquer coatings, joint wood products, composite materials in automotive and aircraft industries, adhesive tapes, multilayer foils for packaging or thin metal films on plastics and optical substrates, e.g., eyeglasses, mirrors, and many more.

Different test stamps are available to cover more than enough material combinations and to enable a wide range of applied loads. In order to facilitate sample preparation specially designed tools are available.

Combine everything you have just read, put it into action, and it makes for not exceptionally accurate and reproducible data, but also for an exceptionally happy user.

More info: watch video "Tests driven by centrifugal force HERE (by courtesy of BAM division 6.7 "Surface Modification and Measurement Technique")

LUMiFrac – the standard in adhesion & cohesion testing.

LUMiFrac® Technology

Centrifugal Adhesion Testing Technology (CATT) – Measure 8 samples simultaneously.

For materials testing, we have developed the Centrifugal Adhesion Testing Technology (CATT) for the comprehensive determination of adhesive, bonding and composite strength.

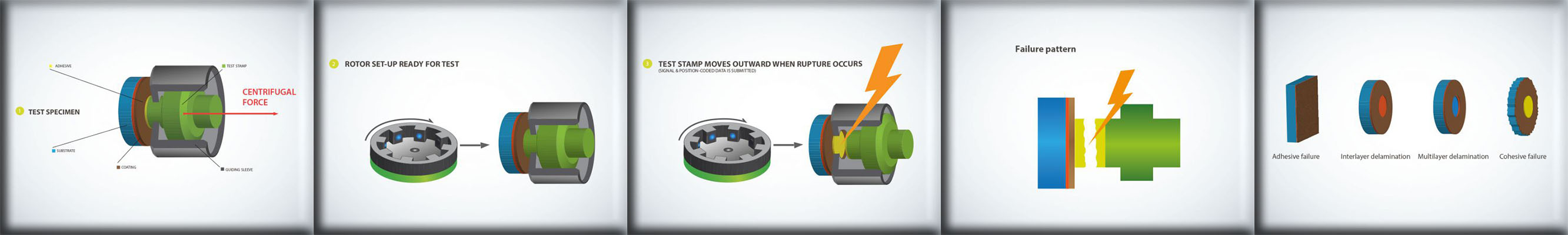

The principle of the new CATT (Centrifugal Adhesion Testing Technology) is as simple as ingenious. Centrifugal force is applied to up to 8 sample assemblies. The load increase is programmed by variation of rotor rpm. If the applied load exceeds the tensile strength of the sample-assembly, the test stamp (TST) changes its position within a guiding sleeve. The detachment of the TST (at the moment of rupture) is automatically detected and a position-coded IR-signal is send out of the turning rotor transmitting the current rotor speed as well as the rupture time. The force at rupture and the tensile strength, either bonding or adhesive strength, is calculated and displayed on-line by measurement software SEPView.

LUMiFrac® Software

SEPView® - Your window to dispersion analysis

SEPView® - Your window to dispersion analysis

| Windows 7 and 8 based | plug and play, pack and go |

| Simultaneous instability index analysis for up to 24 samples in real-time | Allows to save fracture pattern |

| Full SOP concept (Creation, capture, data analysis) | Comprehensive database security and full audit log |

| Complies with 21 CFR Part 11. |

SEPView® is a comprehensive database driven software solution. All data is transmitted and SEPView automatically calculates and displays the critical force/strength of failure in real time. Furthermore, it allows to analyze, compare & calculate statistics and combine results for up to tens of samples. Related data, as figures of fracture pattern, may be taken into account as well.

SEPView controls the instrument and provides functions for data management, visualisation, analysis and result documentation. All information (calibration data, programmed measurement methods, comments, settings etc) is stored in one database, no file management required.

Fast access to validation and measurement results and sample information is guaranteed. Comparison of sample data from different measurements is easily achieved.

The program supports different languages and different systems of units. The modular and object oriented design of the software provides easy extension and customizing opportunities on customer's request, i.e. for special R&D or QC tasks. SEPView complies to CFR 21 Part 11 for special R&D or QC tasks.

LUMiFrac® Industrial Application

The LUMiFrac is used for comprehensive qualitative and quantitative characterization of composite materials, coatings and bonded joints. It is used in a large variety of different industrial and research facilities, dealing with innumerable materials, i. e.

Standardised short time measurements for QC:Testing of tensile strength of bonded joints:

- Cyanoacrylates

- Epoxy adhesives

- Polyurethanes...

Determination of adhesive strength of coatings:

- Anti-corrosion coatings

- Decorative coatings

- Metallized polymers

- Optical coatings...

Long-term fatigue testing:

- Alternating loads

- Different temperatures

LUMiFrac® Specification

| Load range | 0.1 N – 6.5 kN |

| Tensile strength | up to 80 MPa |

| Measurement time | 1 min up to 99 h, depending on task and objective |

| Conformity | ISO 4624; JIS K 5600-5-7; DIN EN 15870; DIN EN 14869-2 |

| Samples | Up to 8 simultaneously |

| Maximal sample dimension | 30 x 30 x >1 mm3 |

| Adhesive area | diameter 7 mm, 10 mm and customized |

| Test stamp material | metals and non-metals |

| Test stamp weight | 4.1 g - 38.7 g (W/Cu up to ca. 58 g) |

| Dimensions (W x H x D) | 380 x 296 x 640 mm3 |

| Rotor speed | 100 – 13,000 rpm |

| Weight | 56 kg, desktop |

| Temperature control | -11°C to + 40°C |

| Data interface | USB |

| Power supply | 100 V / 120 V / 230 V, 50/60 Hz |

| Power consumption | max. 1050 W |